| |

|

|

| |

|

|

|

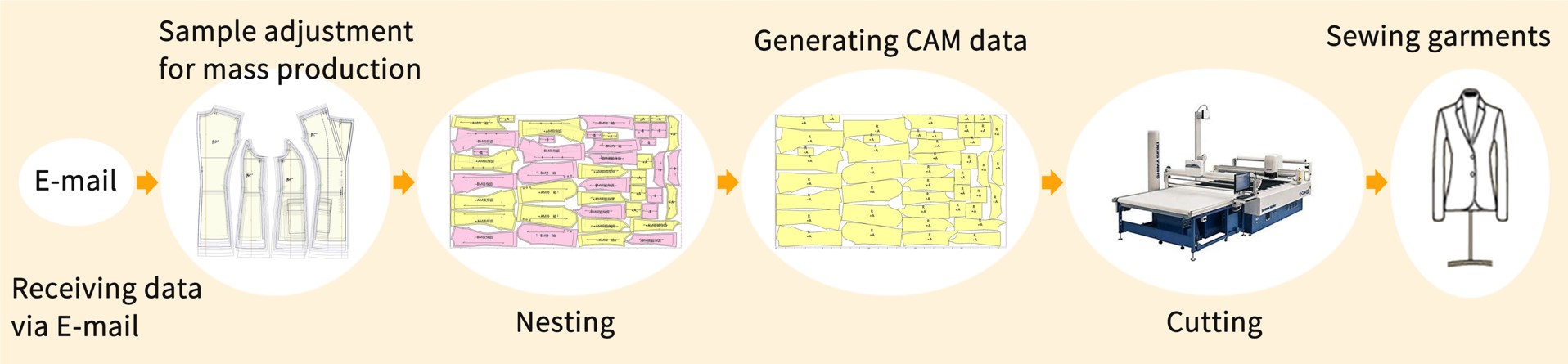

Cut fabric quickly after receiving orders

Simple and efficient tool for mass productions

Reduce material costs and wastes

Continuous version updates and Remote technical supports are available |

|

|

| |

Pattern adjustments section

1. Open data quickly without loss of information

|

|

| 在设计图的基础上,根据已有的服装款式或服装 样板制作新设计方案的首件样衣时,需要输出样 板图纸、剪裁样衣面料、缝合面料以及在人台上 进行试穿,对试穿样衣进行反复确认、修正,最 终达到理想效果并完成样板的定稿。 使用PatternMagicⅡ3D时,基于上述手工作业 的裁剪、缝合、确认、变更、修正以及修正后的 效果显现,均可在虚拟人台上实现数字模拟。 |

|

| |

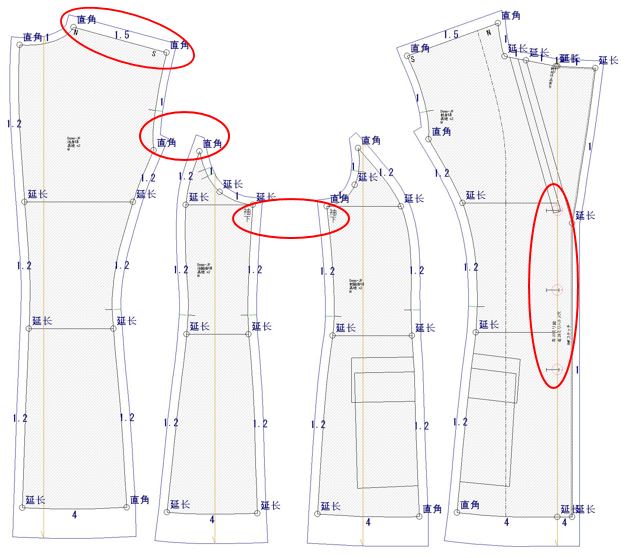

DXF data accounts for a certain proportion of mass production. TORAY CAD opens DXF data, keeping all information, such as seam allowance and clothing instructions. No need to re-enter information lost during conversion. |

|

|

|

|

| |

2. One menu to complete the modification for the

mass productions

|

|

| |

In mass production, it is essential to adjust the seam allowance according to the production process.

TORAY CAD can edit all sizes at once, making adjustments easy. |

|

|

|

| |

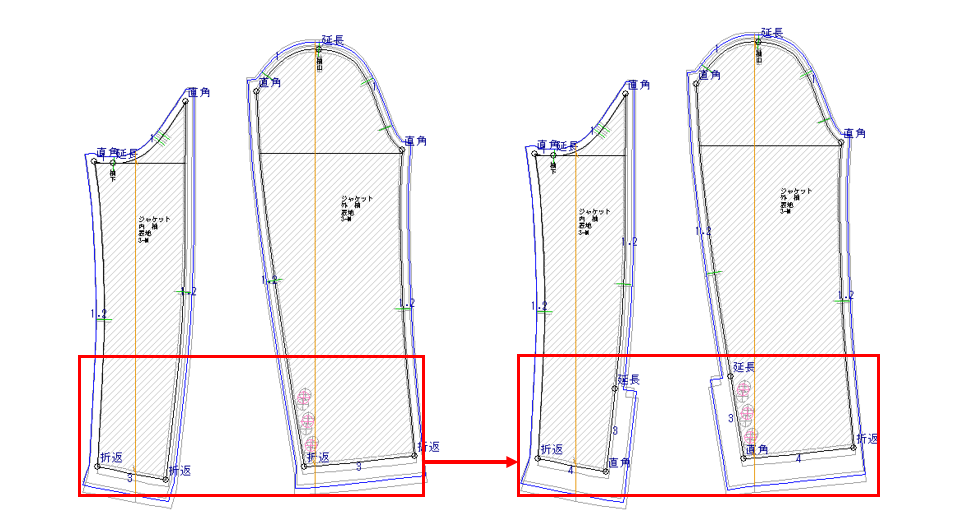

3. Seam allowance adjustment

|

|

| |

"All Size Mode” allows you to change all seam allowance with one click, regardless of its size or angle. |

|

| |

|

|

| |

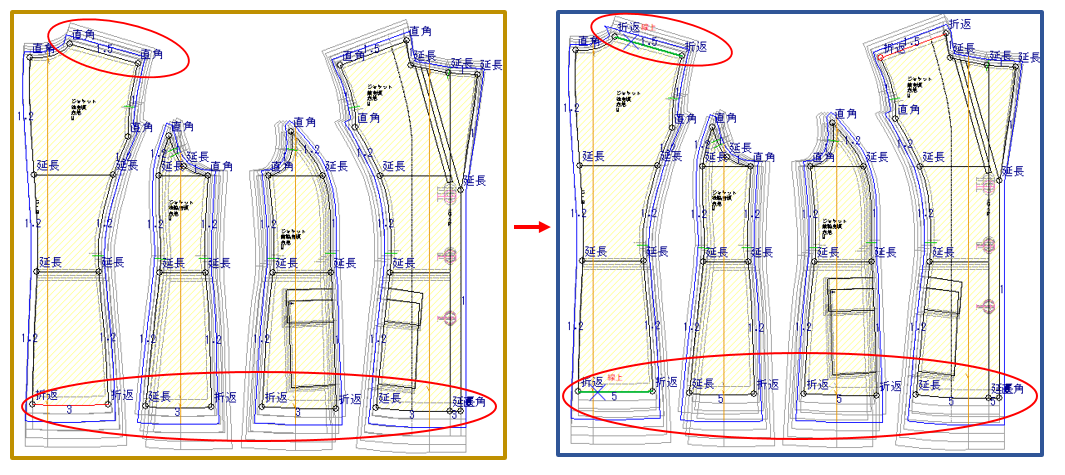

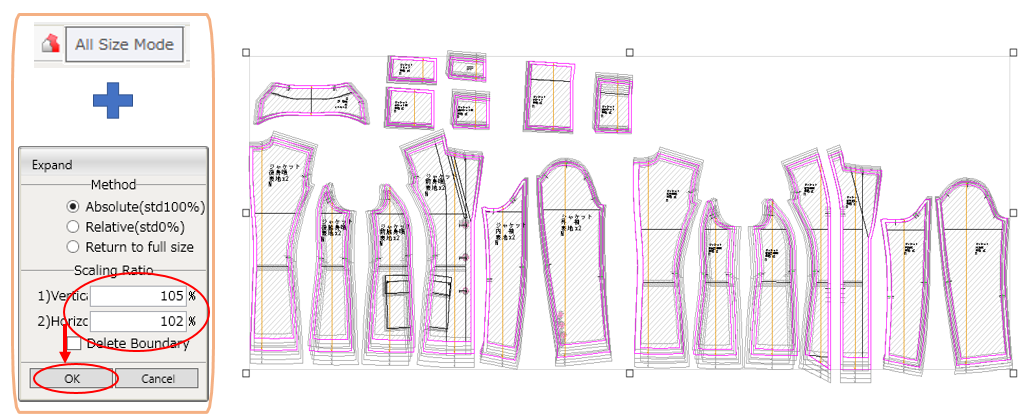

4. Shrinkage adjustment

|

|

| |

Before mass production, it's usually necessary to do shrinkage adjustments, considering fabric property and changing after washing.

"All Size Mode" + "Expand" allows you to adjust shrinkage with one click. |

|

| |

|

|

| |

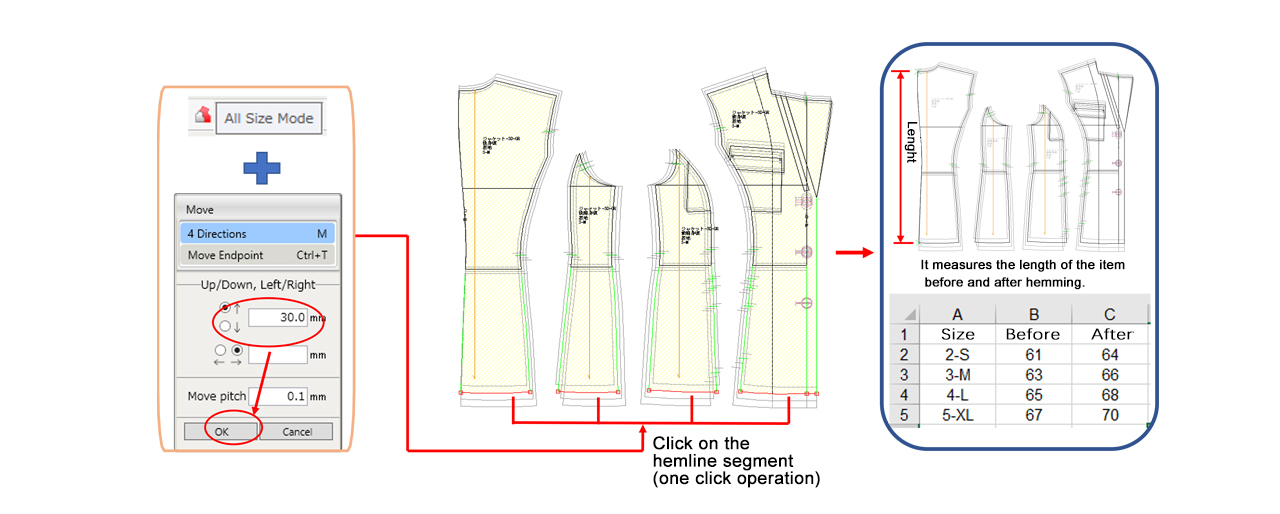

5-1 Length adjustment

|

|

| |

All sizes can be modified with one click with the "All Size Mode", which makes you change an extensive amount of mass production data. Let's take an example of mass production where you need to make it 3 cm longer because of different sewing techniques. |

|

| |

|

|

| |

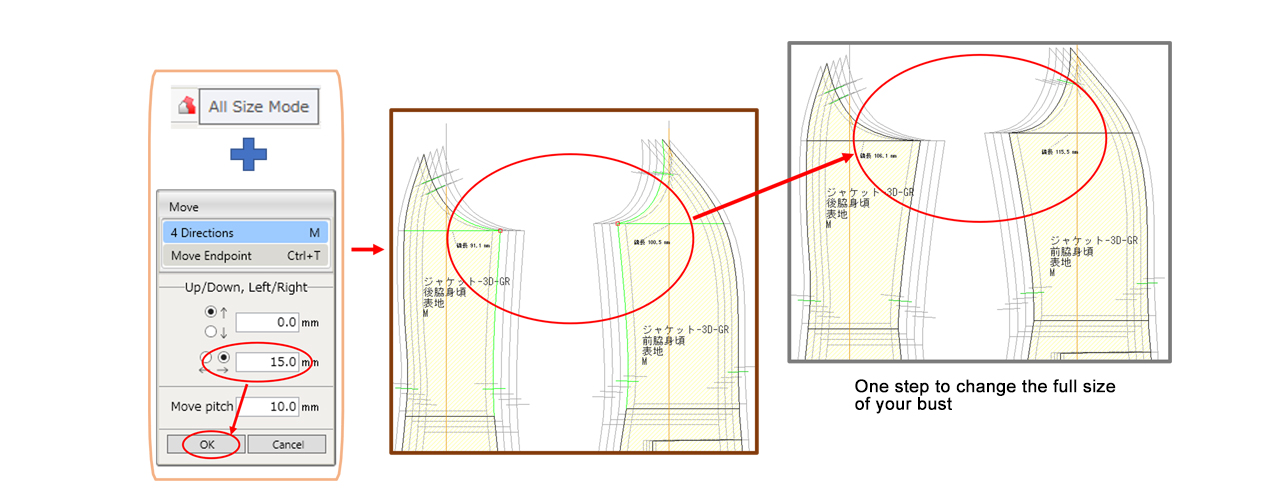

5-2 Bust/waist/hip adjustments |

|

| |

You can adjust Bust/waist/hip size in the same way.

Ex) the bust needs to be increased by 6 cm. |

|

| |

|

|

| |

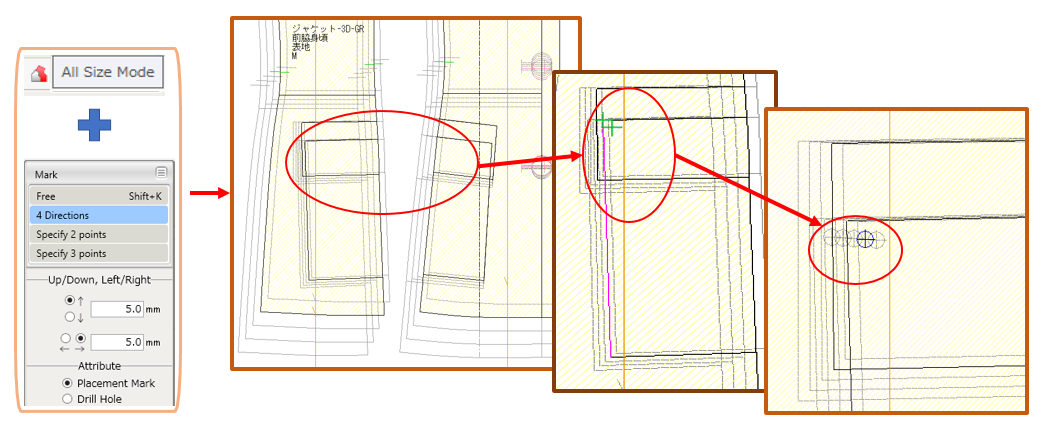

6. Positioning hole

|

|

| |

Pocket positions, and dart tips, or else, all require positioning markings to be set at the time of sewing, and all sizes can be added with a single click. |

|

| |

|

|

| |

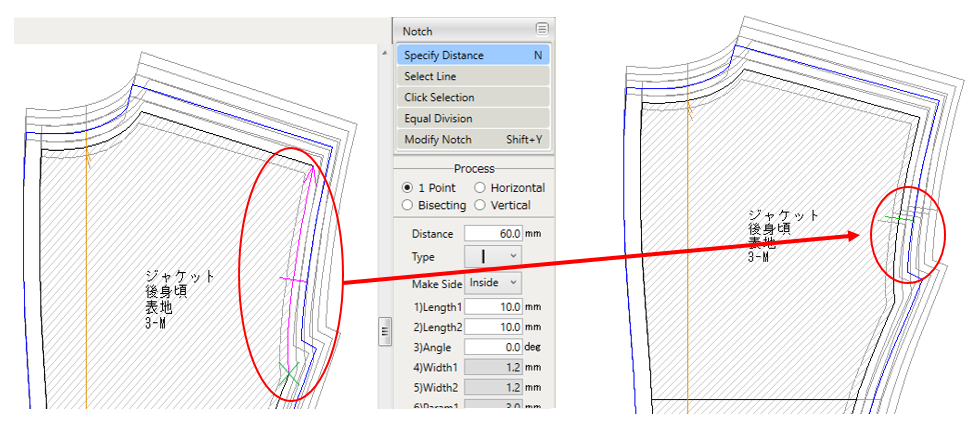

7. Notch

|

|

| |

All sizes are one click away from adding the notches required for later sewing. |

|

| |

|

|

| |

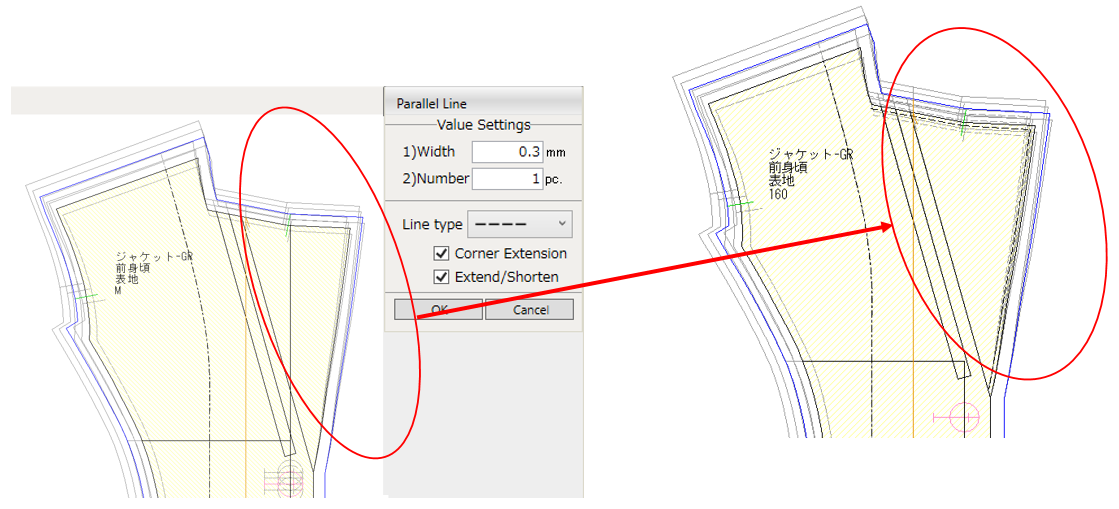

8. Parallel Line

|

|

| |

All size lines can be added with one click. |

|

| |

|

|

| |

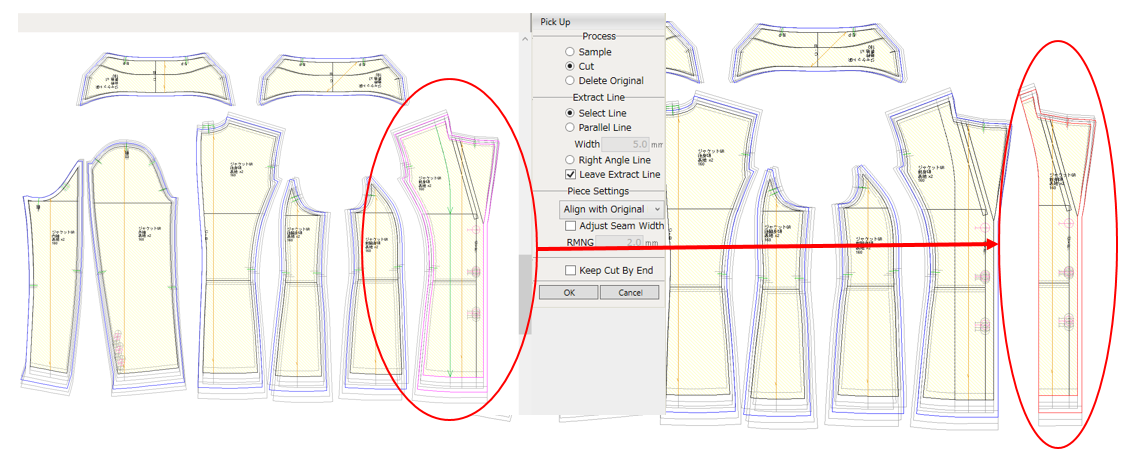

9. Pick Up

|

|

| |

To take out patterns as shown in the picture, four sizes can be removed in one go. |

|

| |

|

|

| |

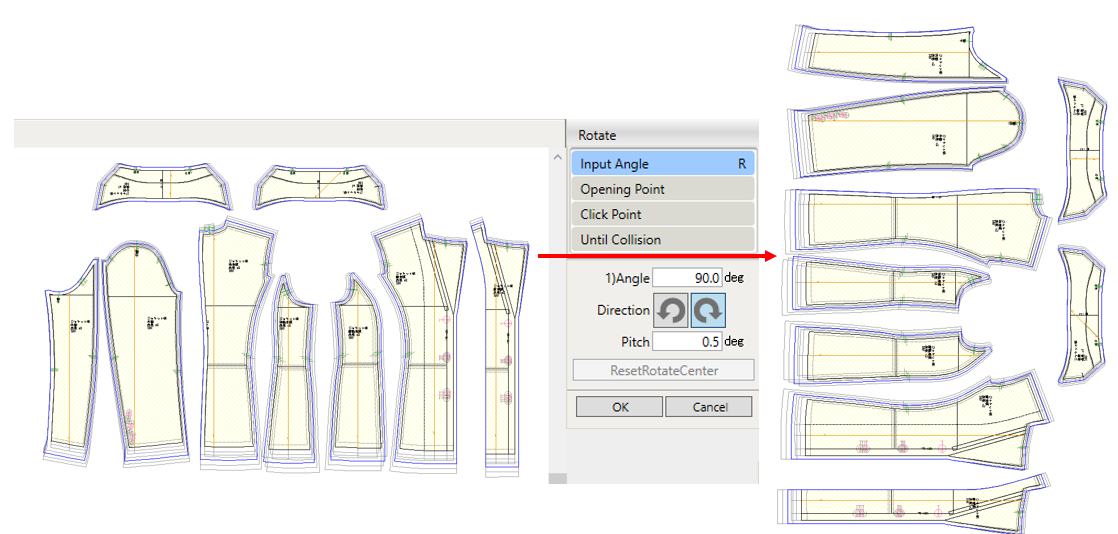

10. Rotate

|

|

| |

The imported data can be rotated in all sizes with one click as you like. |

|

| |

|

|

| |

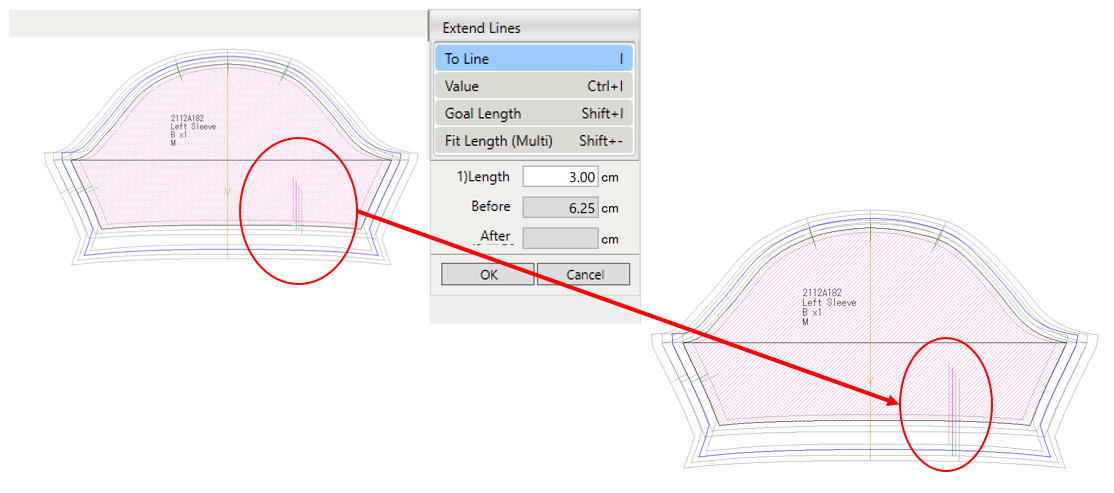

11. Extension and shortening

|

|

| |

The lines of the mass production data can be extended/shortened for all sizes at once. |

|

| |

|

|

| |

12.Setting of CAM cutting lines

|

|

| |

The CAM cutting lines for all sizes can be set with one click for mass production. |

|

| |

|

|

| |

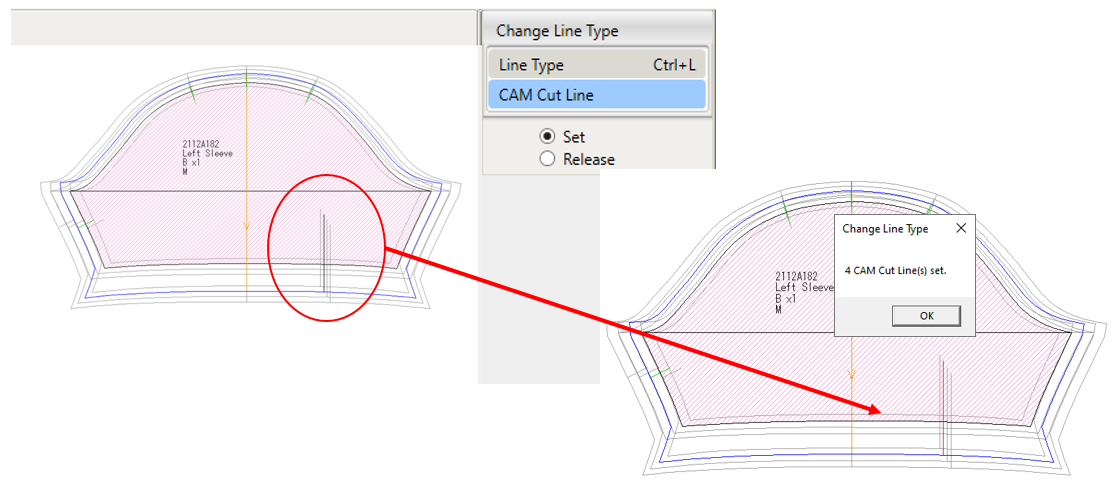

13. Very easy to calculate the amount of filling

|

|

| |

It calculates the amount of feather filling for down garments simultaneously.

|

|

| |

|

|

| |

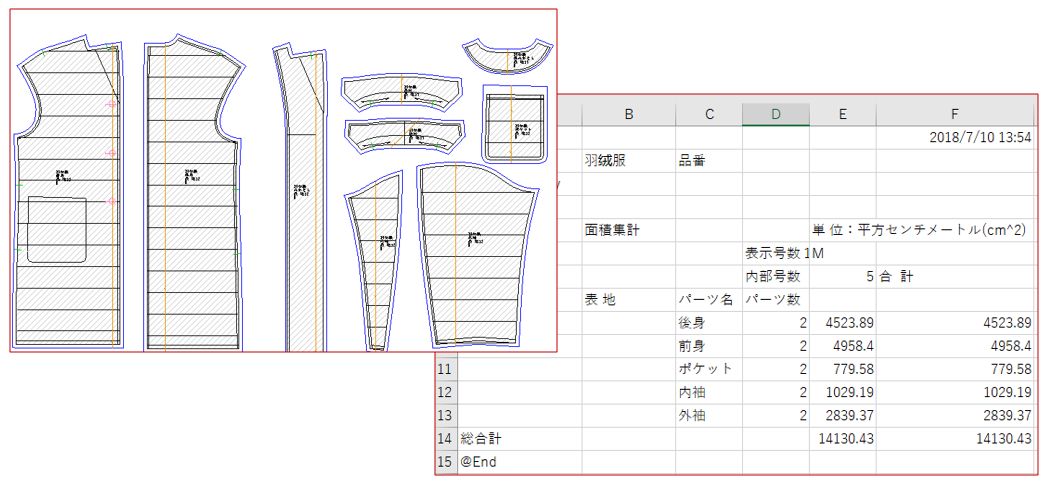

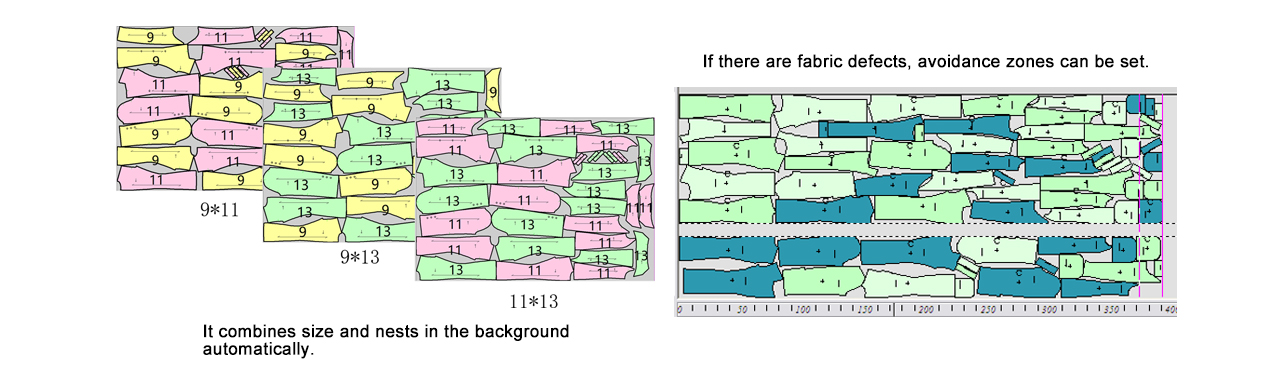

Automatic nesting section

14. Multi-size matrix

|

|

| |

With the matrix function, the selection of garment pieces from multiple sizes is easy and it can be nest automatically. |

|

| |

|

|

| |

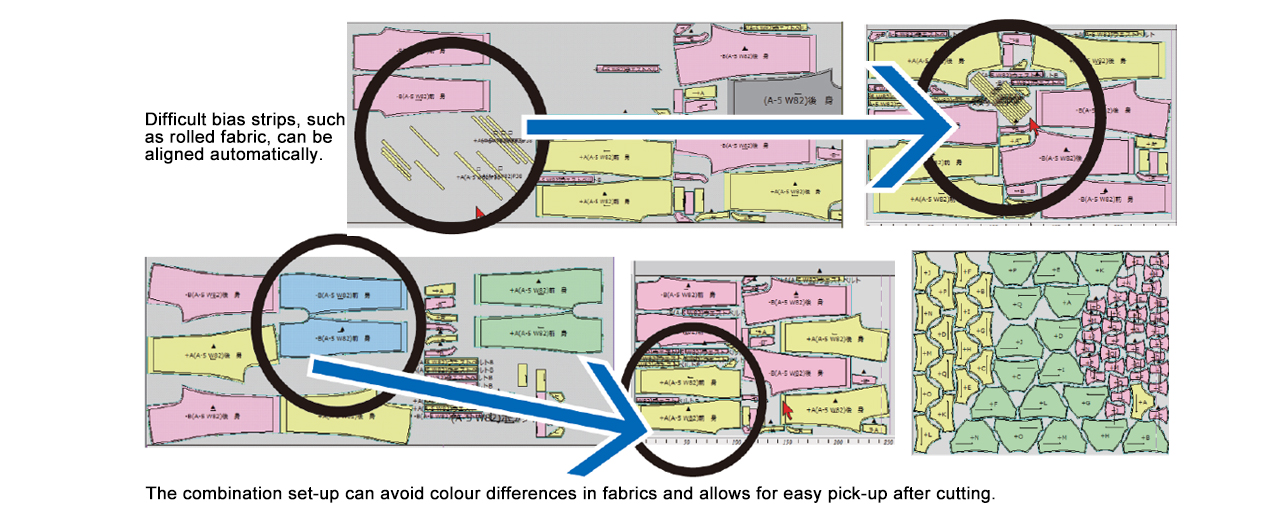

15. Pattern match

|

|

| |

Pattern match function for checked and striped fabrics can solve the problem of hand laying out the material.

|

|

| |

|

|

| |

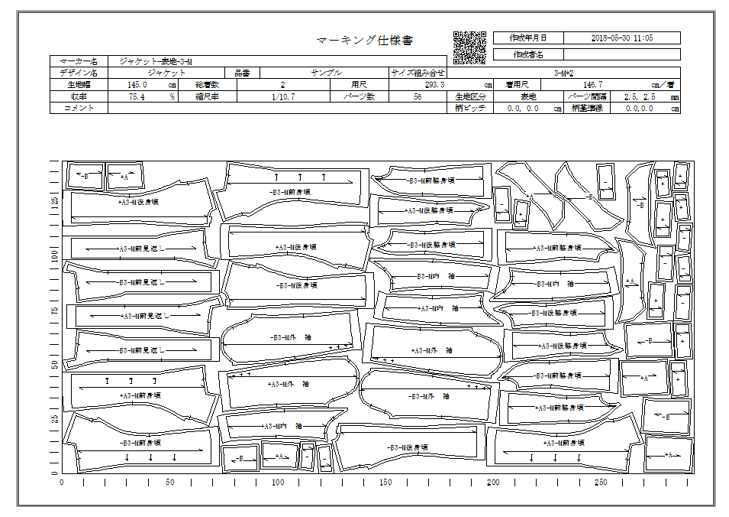

16. Output of nesting result

|

|

| |

For customs clearance, when importing and exporting fabrics or archiving, you can output nesting result as PDF.

|

|

| |

|

|

| |

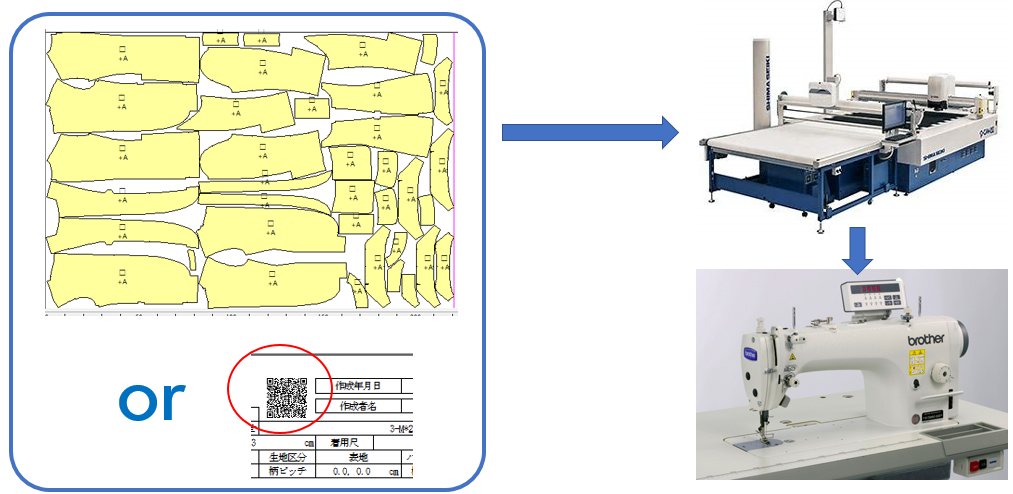

17. CAM data generation and output

|

|

| |

Once the nesting is complete, the cutting data is directly exported and sent to the cutting machine for the next process, sewing (QR code output supported).

|

|

| |

|

|

| |

Appendix 1-1: "Auto Advance II", an automatic nestingfunction (optional)

|

|

| |

Efficient and material-saving automatic nesting software for CAM

|

|

| |

|

|

| |

Appendix 1-2: "Auto Advance II", an automatic nestingfunction (optional)

|

|

| |

|

|

|

Appendix 3: List of compatible input and output devices |

|

| 在设计图的基础上,根据已有的服装款式或服装 样板制作新设计方案的首件样衣时,需要输出样 板图纸、剪裁样衣面料、缝合面料以及在人台上 进行试穿,对试穿样衣进行反复确认、修正,最 终达到理想效果并完成样板的定稿。 使用PatternMagicⅡ3D时,基于上述手工作业 的裁剪、缝合、确认、变更、修正以及修正后的 效果显现,均可在虚拟人台上实现数字模拟。 |

|

A0 Scanners |

|

| Brands

|

Country of origin |

Model |

Remarks |

Graphtec |

JAPAN |

CSX510-09 |

A0 size paper sample scanner Workstation is required.

Some models with LAN interface is required. |

CSX530-09 |

CSX550-09 |

|

|

Cutter / Plotters |

|

| Brands

|

Country of origin |

Model |

Remarks |

Mimaki |

JAPAN |

APC-130 (1200㎜) |

|

FC2-0912(1170mm×1200mm) |

Capable of cutting hard materials. |

FC2-1215(1470mm×1500mm) |

FC2-1218(1770mm×1800mm) |

Graphtec |

CE6000-120AP(1200mm) |

|

CE7000-120AP(1200mm) |

FCX2000-120 (VC )(1200mmx920mm) |

|

FCX2000-180 (VC) (1800mmx920mm) |

|

|

| |

Appendix 3: List of compatible input and output devices |

|

| |

Cutter / Plotters |

|

| Brands

|

Country of origin |

Model |

Remarks |

JWEI |

CHINA |

EDO「Series」 |

Need to confirm output centre and driver support for WIN10 Pro systems |

ICII「Series」 |

|

| |

Inkjet Printer |

|

| Brands

|

Country of origin |

Model |

Remarks |

NEW POWER |

CHINA |

LH「Series」 |

Need to confirm output centre and driver support for WIN10 Pro systems |

SINAJET |

POPJET「Series」 |

|

| |

CAM |

|

| Brands

|

Country of origin |

Model |

Remarks |

SHIMA SEIKI |

JAPAN |

P-CAM |

All cutting machines require prior Cut-off data cutting confirmation |

Takatori |

TAC-VN |

TAC-M |

KAWAKAMI |

GP-50 / 70 |

LECTRA |

France |

Vector Fashion |

GERBER |

United States |

Gerber Atria |

|